Instructions for communicating Modbus of Danfoss FC360 inverter with Mitsubishi FX3U PLC

With technical development, the control cabinets nowadays use multiple communication to aim at strengthening the monitoring and minimizing external intermediary devices. Modbus standards are popular and available in all inverter lines and. Using Modbus available in inverter helps to reduce PLC input and output costs make electrical cabinets more beautiful by less wiring and minimizing intermediate devices. Moreover, it helps us to monitor all parameters of inverter, status, error … easily.

1. Introduction FC360

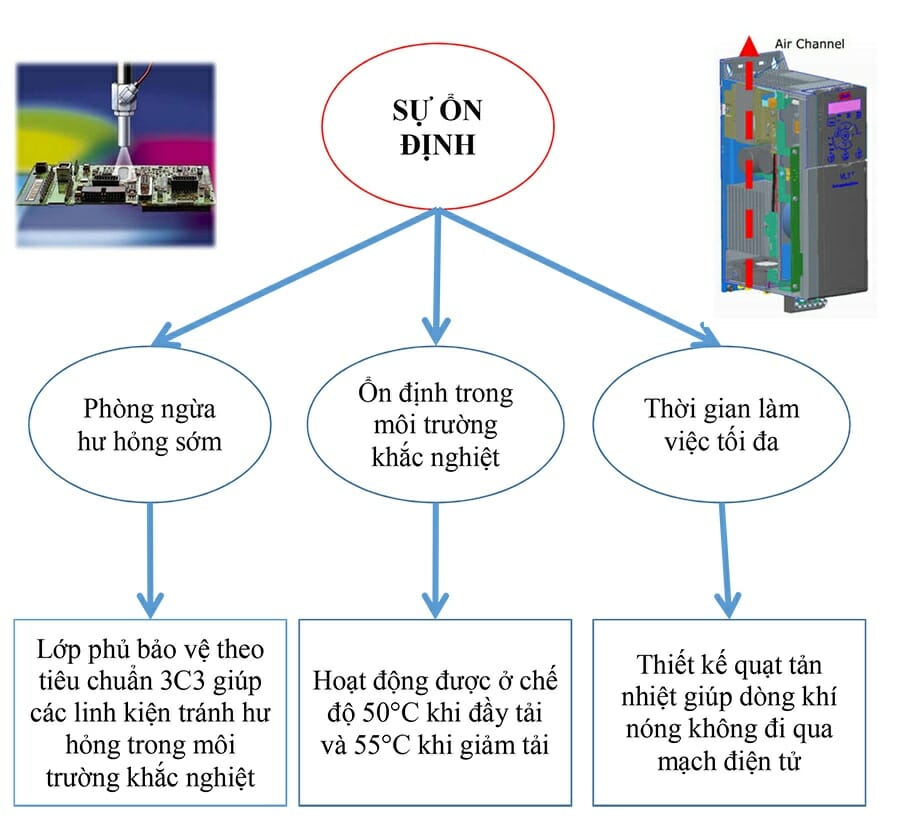

FC360 inverter is Danfoss’s versatile inverter series, widely used in the industry.

- Supply voltage: 3 phase 380-480 V (-15% / + 10%).

- Product range: 0.37-75 Kw. (90kw with light load)

- Displacement Power Factor > 0.98

- Supply frequency: 50/60 Hz.

- Enclosure ratings: IP20

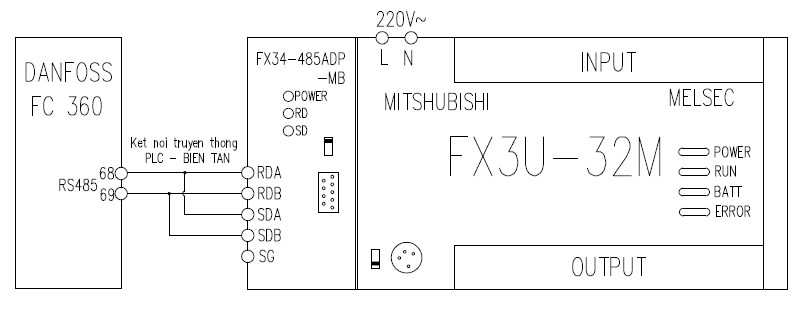

2. Diagram of connecting between FC360 inverter and FX3U PLC

3. Installing modbus RTU communication parameters for Danfoss FC360 inverter:

| Code | Function | Value |

| 8-30 | Communication protocol | [2] Modbus RTU |

| 8-31 | Inverter Address | 1 |

| 8-32 | Baud speed | [2] 9600 |

| 8-33 | Party/Stop bit | [0] Even Parity, 1 Stop Bit |

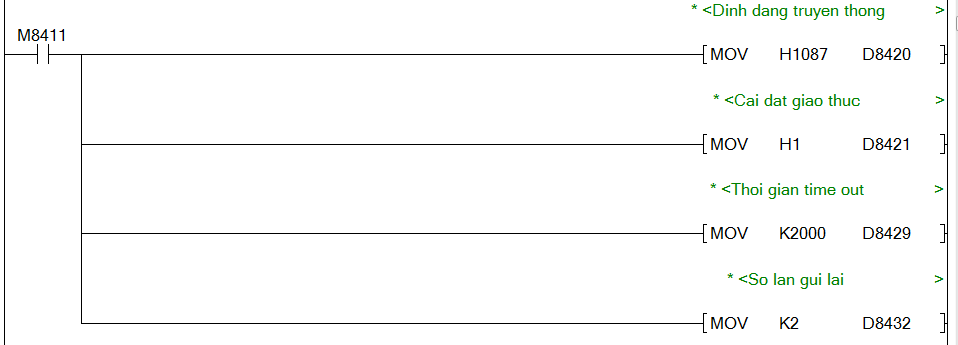

- Set the time-out time in D8429 register: After this time if the inverter does not respond to the PLC’s request, the PLC will resend the request to the inverter with the time set in the D8429 register. Set the value K2000 corresponding to a time is 2000ms.

- Set the requesting number in the D8432 register: After the time-out interval, PLC will resend the request to the inverter with the number times set in the D8432 register. Set the value of K2 corresponding to the requesting number is 2 times.

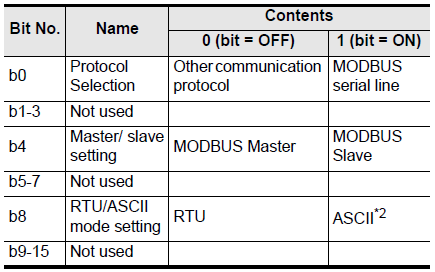

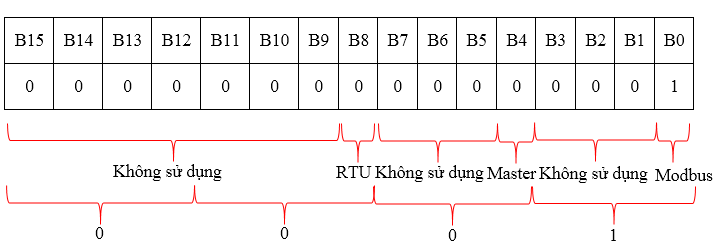

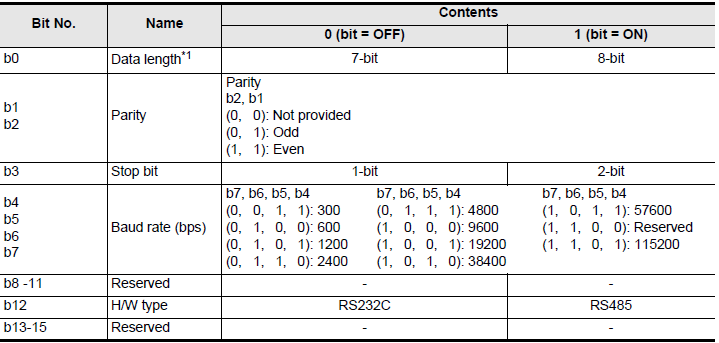

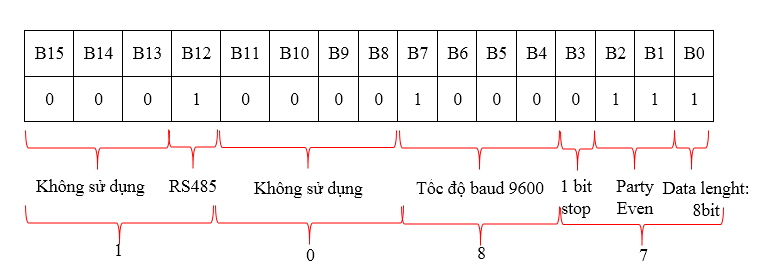

- Configuring PLC communication

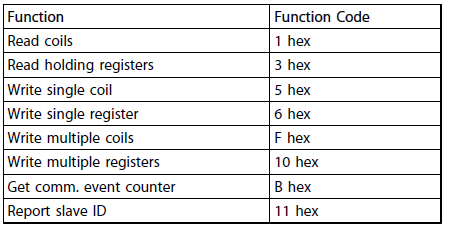

Danfoss FC360 inverters support code

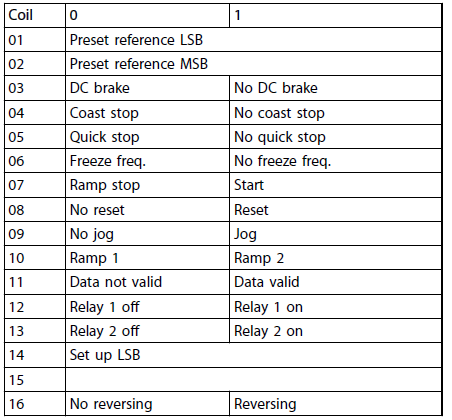

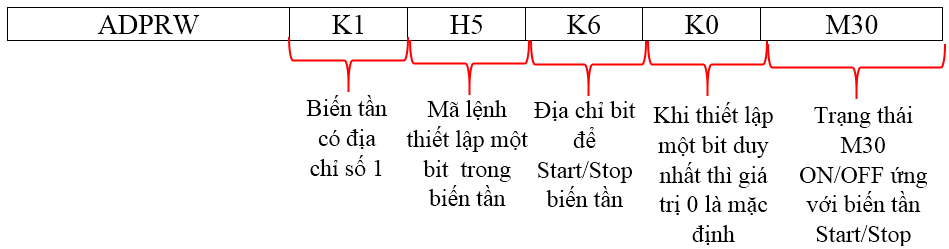

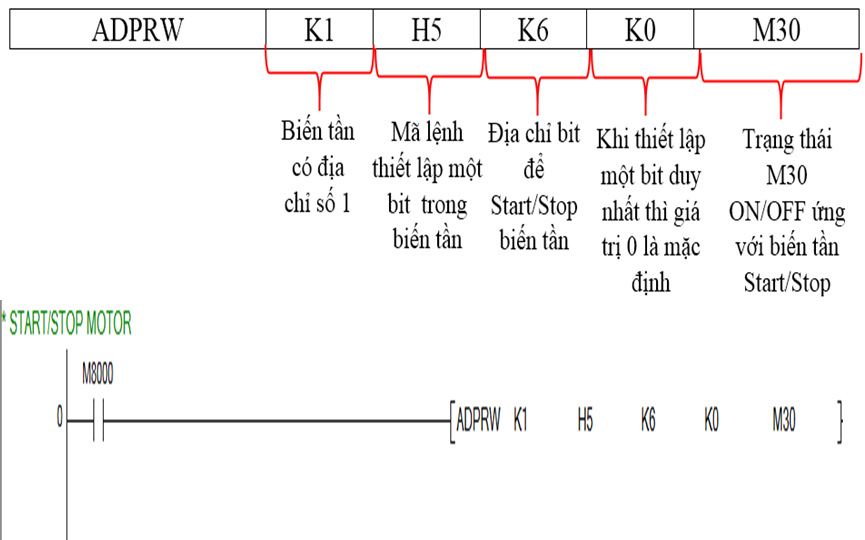

- Start/Stop động cơ:

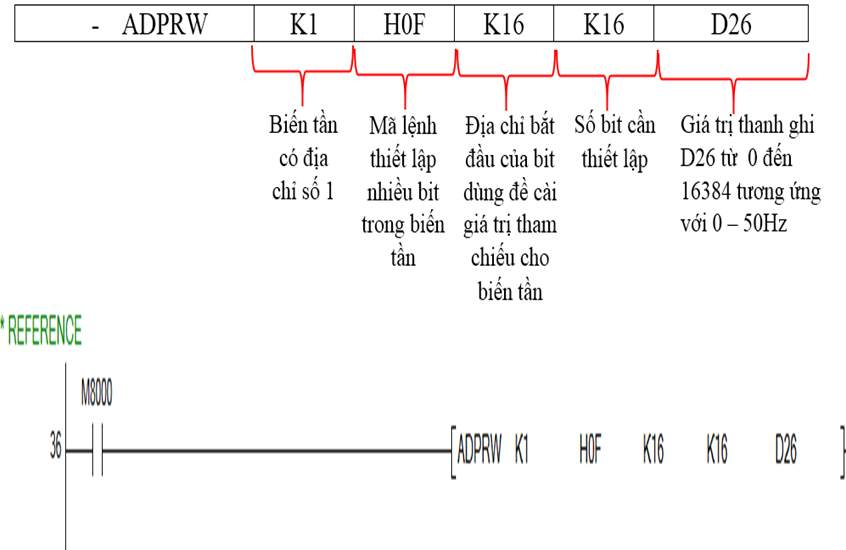

Đặt tốc độ biến tần từ PLC: Cài đặt thông số biến tần 3-15 = [11] Local Bus Reference

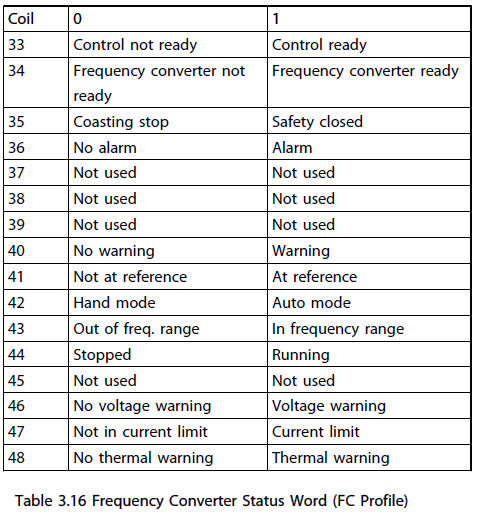

- Đọc thông số động cơ: tần số, điện áp, dòng điện, công suất