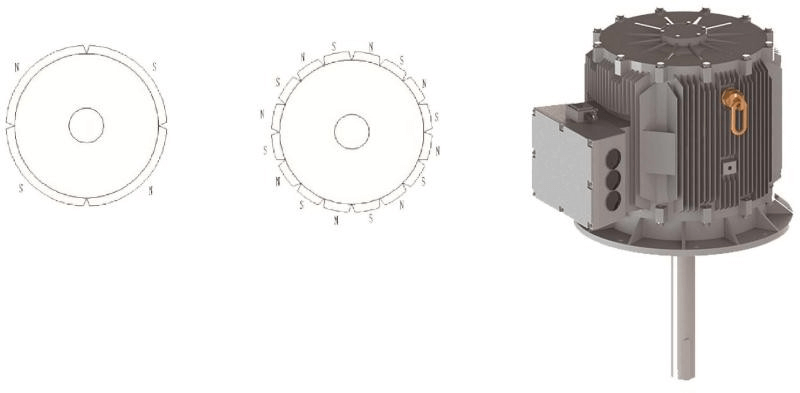

Synchronous Permanent magnet motor

Qingdao Enneng Motor Co., Ltd (abbreviated as “ENNENG”) is a high-tech enterprise integrating R& D and manufacturing of permanent magnet motors.

ENNENG is devoted to the research and development of various special high & low voltage low-speed high-torque permament magnet motors, constant-speed permanent magnet motors, and special direct-drive permanent magnet motors.

ENNENG permanent magnet motors are widely used in the different fields including gold mine, coal mine, tire factory, oil well, and water treatment plants, which have benefited the customers for energy saving as well as for environmental protection.

CÁC DÒNG SẢN PHẨM

Main features

- High efficiency energy-saving: The chosen high performance rare earth permanent magnet material and special stator groove and rotor structure make the motor efficiency reach IE4

standard. - Small & lightweight: By reducing frame No. by one to three, compared to the same power asynchronous motor, it (standard type) is more compact.

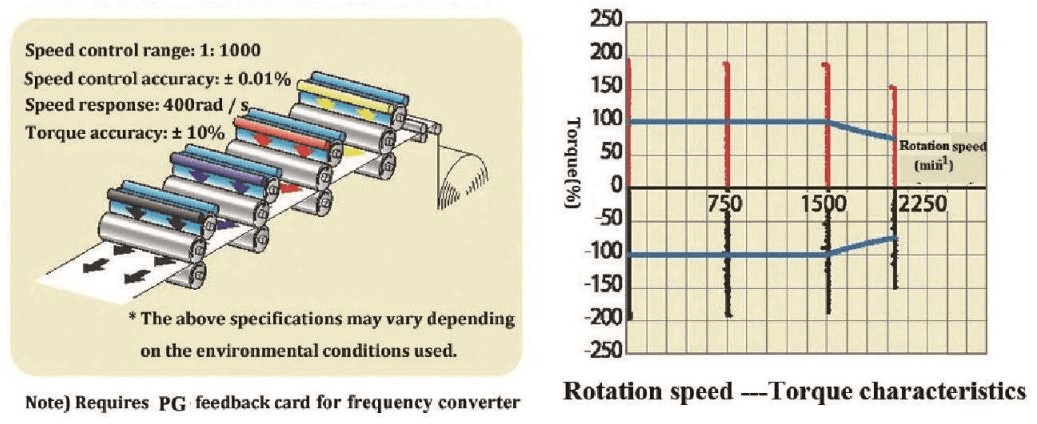

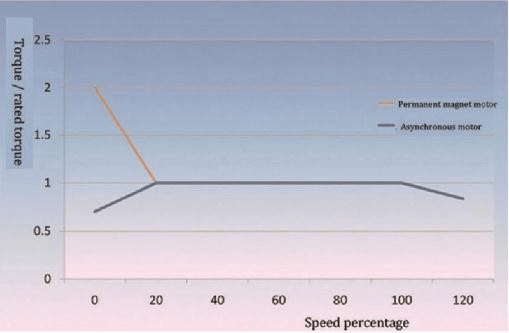

- High performance: Smaller rotary inertia, larger starting torque and wider operating frequency.

- High reliability: Lower current, lower temperature rise, lower running noise and longer motor life.

- Wide universality: Due to the same structure with asynchronous motor, it (general type) can directly replace the asynchronous motor.

- Simple control: The variable frequency vector control mode adopted can improve control precision and reduce failures.

- Modular design: Flexible setting with various modules such as independent drive fan, encoder, brake, etc.

- High feasibility: Applicable in all kinds of bad conditions, even in long time running at low speed, frequent start-up and other occasions

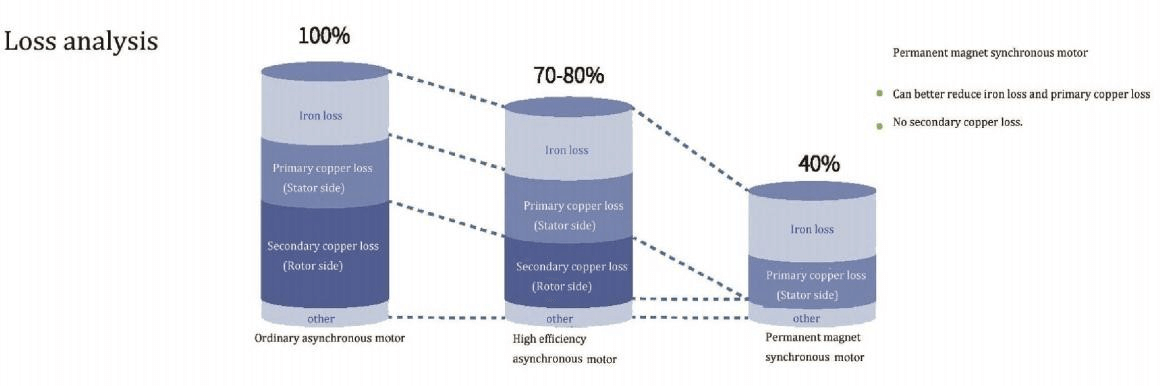

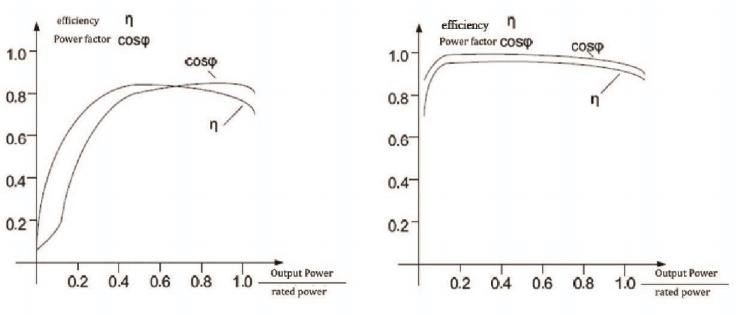

Adopt high-efficiency neodymium-iron-boron permanent magnet, no excitation loss, through special rotor structure design, greatly reduce iron loss and stray loss, the whole machine efficiency reaches above IE4 standard, which is 5-10% higher than three-phase asynchronous

motor efficiency, and power factor is improved 10-15% or more.

It can maintain high efficiency and power factor in the load range of 20%-120%. The power factor can be 1, and the three-phase asynchronous motor can only reach 0.86. It has effectively reduced the line loss, more significant energy saving at light load, and improved the utilization rate of the power grid.

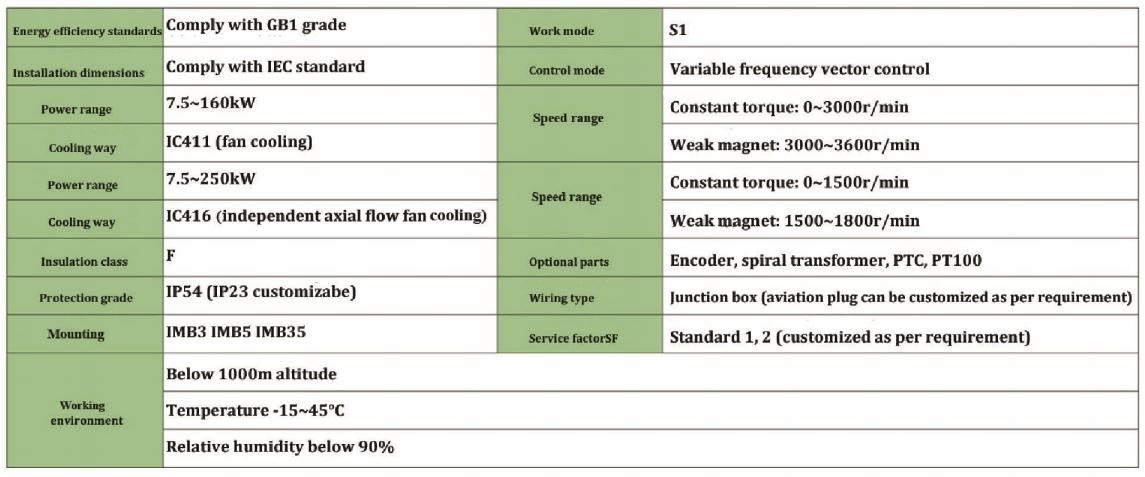

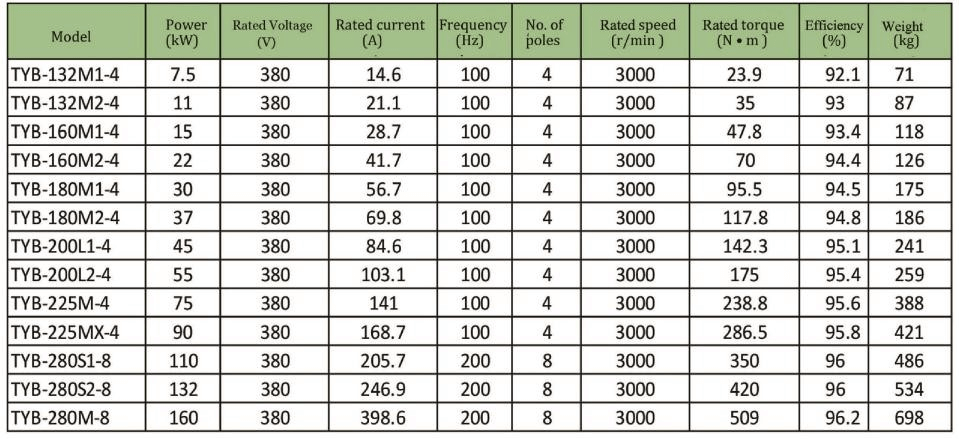

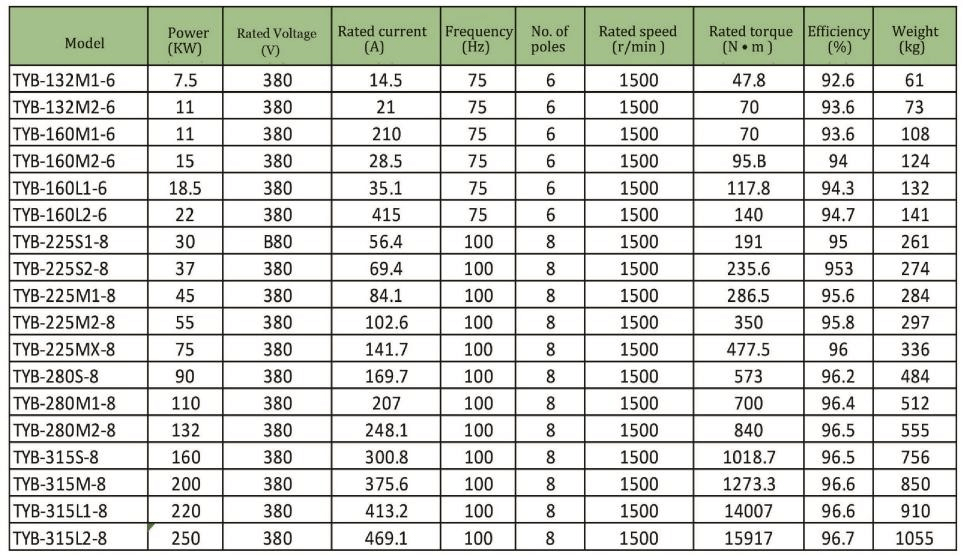

ĐỘNG CƠ DÒNG TIÊU CHUẨN TYB:

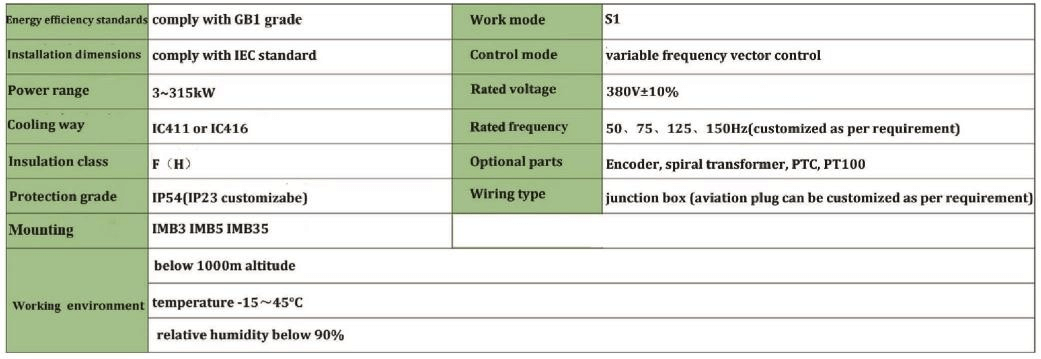

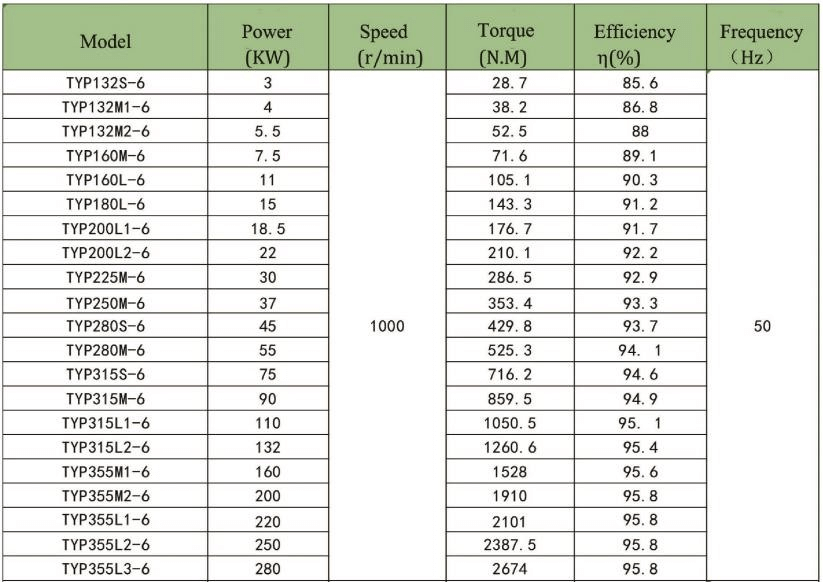

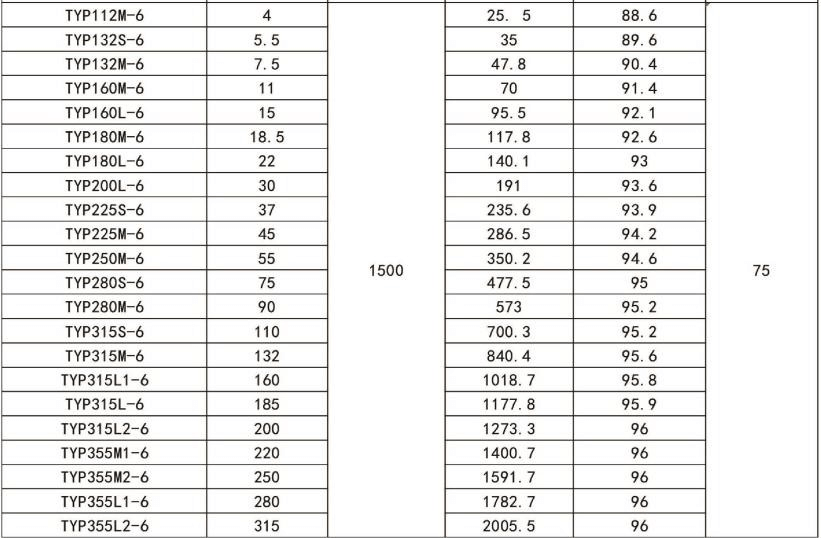

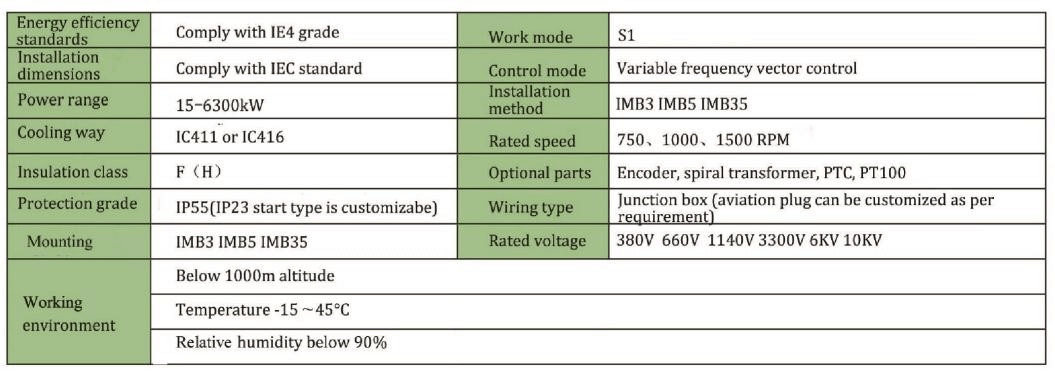

General type TYP series:

- Due to the same frame No. Design with asynchronous motor (output < 315 kW) it can be easily changed.

- High power factor.

- Speed control corresponding to height.

- Motor efficiency is higher than IE4 (ultra high efficiency: above GB1 grade)

Special type TYPCX series:

- Due to the same motor frame No. Design with asynchronous motor (output < 280 kW), it can be easily changed. Some types of motors are longer than asynchronous motor. Details refer to outer dimension drawing.

- Motor efficiency is higher than IE4 (ultra high efficiency: above GB1 grade)

- Speed control corresponding to height. It can be PG vector controlled!

Direct-drive type TYPD series:

- Due to the use of permanent magnet to provide magnetic field, rotor process is mature, reliable, size is flexible, and its design power range from dozens of watts to megawatts. At the same time, by increasing or decreasing the pair numbers of permanent magnets in the rotor, it is easier to change the number of poles of the motor, so that the speed range of the permanent magnet synchronous motor is comparatively wider. The use of multipole permanent magnet rotor, the rate speed can be as low as single digit, which is difficult to achieve by ordinary asynchronous motor.

- Especially in the application environment of low speed and high power, permanent magnet synchronous motor can adopt multi-pole direct drive at low speed. Compared with ordinary motor plus speed reducer, the advantages of permanent magnet synchronous motor are prominent

- The special low-speed and high-power permanent magnet drive system adopts optimal design: the motor itself has a higher efficiency up to 93-97%, and a higher power factor up to 0.99, which increases the proportion of active power in the system. At the same time, the

transmission efficiency of the whole equipment is higher than that of the high-speed motor + gearbox because no gearbox transmission is required. - For example, the average load rate of the motor in the whole running process from starting, running to stopping is about 40%, while the maximum load rate is less than 60%.Since the efficiency and power factor of the asynchronous motor are closely related to the load rate,

when the load rate is lower than 50%, the efficiency and power factors drop sharply. The efficiency and power factors of permanent magnet motor are less affected by the load rate, and can still keep extremely high efficiency and power factor within the load rate of 20% ~ 120%.

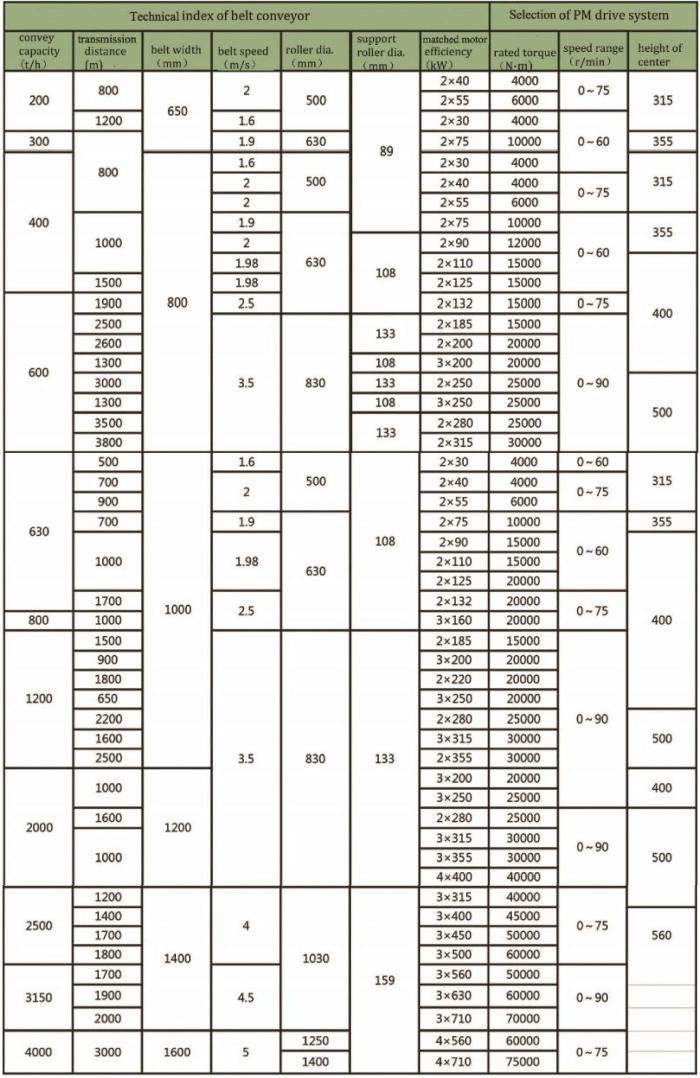

Special permanent magnet direct drive motor for belt conveyor

- Determine the motor speed range according to the belt speed and roller outer diameter of the belt conveyor, to select the motor drive system whose speed range is not less than and closest to the actual demand. The standard rated speed is 0-60r/min, 0-75r/min, 0-90r/min, and other speed range can be adjusted and customized according to the actual requirements of customers.

- Confirm the torque required by the belt conveyor first to select the appropriate permanent magnet drive system. The actual torque of the equipment can also be calculated according to the parameters of traditional asynchronous motor and the speed ratio of reducer.

- Determine the rated voltage of the motor. The common voltage of the motor under the torque of 30000N.m is 380V, 660V, 1140v. The motor voltage above the torque of 30000N.m is 1140V, 2300V, 6kV, 10kV. Other voltage levels can be customized according to customer needs.

No products were found matching your selection.