Description

Product range

– 0.25 – 37 kW (200 – 240 V)

– 0.37 kW – 1 MW (380 – 500 V)

– 0.75 – 75 KW (525 – 600V)

– 1.1 kW – 1.2 MW (525 – 690V)

Coated circuit boards

The VLT® AutomationDrive conforms to class 3C2 (IEC 60721-3-3) as standard. If used in especially harsh conditions it is possible to order a special coating that complies with class 3C3.

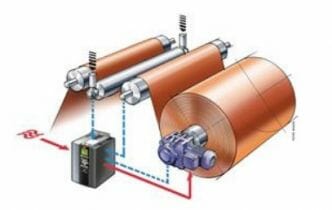

When torque is the issue

In all winders the torque required to accelerate and decelerate an application varies with the load. With centre winders the required torque even varies with the dimension of the roll. Torque mode with a high precision torque control is needed.

It is essential in winding operations to fully control the tension of the material being wound. To maintain tangential tension independently of the line speed and roll diameter, the drive is able to dynamically follow a wide range of torque references.

Encoder check

The drive will automatically check and verify if the encoder is malfunctioning.

The feedback from the encoder is compared with a calculated speed.

VLT® AutomationDrive FC 302 runs permanent magnet motors

VLT® AutomationDrive FC 302 exploits full potential of per-manent magnet motors in high dynamic applications.

Fast processors enable it to precisely control position, acceleration and torque.

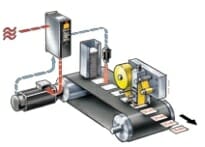

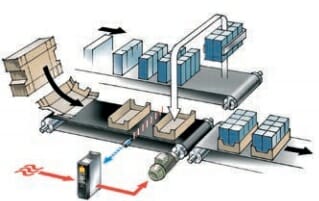

Add flexibility to precision

The new VLT® AutomationDrive lets you alter production speed without rebuilding the conveyor. The Precise Pulse Stop feature ensures that products always are where they should be on the line.

Speed or slow the entire line

Production speed can be changed at any time, even if the application involves several sections. The Precise Pulse Reference feature makes the conveyors follow the encoder from master conveyor or virtual master drive, ensuring that all conveyors are in sync.

Benefits

The conveyor can be stopped at a precise location using an open loop system independent of production speed. Precise Pulse Stop compensates for the speed of the object when it passes the stop sensor. This results in a precise stop, regardless of production speed.