Industrial energy saving solutions

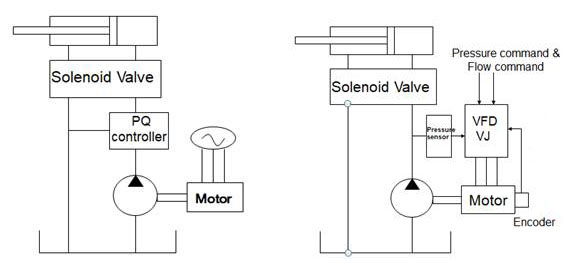

1. INJECTIONS MOUDING MACHINE

Traditional system with fix pump and induction motor be replaced by modern system with servo pump can save up to 70% energy and reduce hydraulic oil temperature also

2. NH3 GAS COMPRESSOR

Depend on cold temperature in cold storage, at the beginning the storage is still not cold there is high volume of NH3 liquid go to the evaporator to exchange the heat the transform to NH3 gas go to inlet of the compressor. At this time, the compressor is running full load. However, when the storage cold enough, the NH3 liquid come to evaporator reduce so the gas come to compressor also reduce mean compressor is working low load.

Our solution is sensing the pressure of NH3 gas then adjusts the speed of compressor in order to saving energy.

3. AIR COOLED CONDENSER

Condenser is used to cool down the temperature of NH3 gas. Depend on the volume of NH3 gas and ambient temperature we can install inverter to adjust speed of cooling fan to save energy

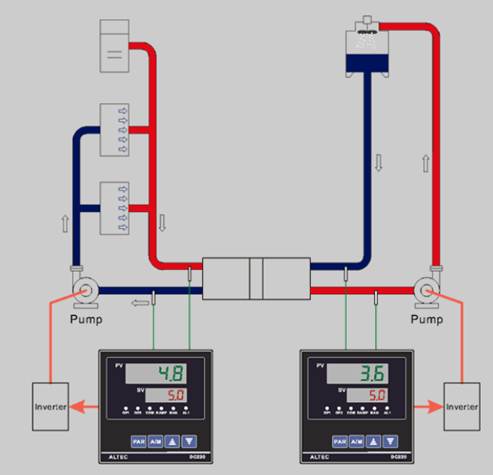

4. COOLING TOWER

Hot water need to cool down by cooling tower. By sensing the difference of temperature between inlet and outlet of cooling tower we can adjust speed of cooling fan enough to save energy

We also can save energy by controlling the flow rate of cooling water and hot water as below picture

5. AIR COMPRESSOR

Depend on the need of compressed air, compressor is often working in load and unload stage. When output pressure reach high limit, compressor will be switch to unload stage until output pressure drop to low limit it will be switch to load stage again.

Our solution is install inverter to control speed of compressor adapt with required pressure and saving energy.

6. DUST COLLECTOR SYSTEM IN WOOD FACTORY

The dust collector fan is running continuously to collect all dust from all machines in factory. However, in ordinary operation, there are some machines in idle stage while other still working. At the idle machine, workers close the tap of collector pipe so the exhaust pressure at other machine will be stronger. It mean we can install inverter to control the pressure be constant all the time to save energy.

7. VACUUM PUMP/FAN

Energy saving solution for vacuum system is same at dust collecting system

8. CENTRIFUGAL MACHINE

Centrifugal machine has high inertia so stopping time is often very long and during that time, the motor generating electricity to the inverter so we can install the dynamic regenerating braking unit to collect this electricity or can apply the new matrix inverter to save energy and increase productivity by reducing stopping time

9. GRINDING MACHINE

Grinding machine often work with low load as material supplied un-continuous as full status. It means we can reduce motor speed to save energy

10. UNWINDING APPLICATIONS

In unwinding application, the motor is always pulled by material and It has to run in revert direction to maintain the tension of material coil so the motor always generate electricity to inverter. In this case, we also can install the regenerative braking unit or Matrix inverter

11. LIFTING APPLICATIONS

During moving down period, the motor is pulled down by load. The heavier load the stronger pull force mean the more energy can save. The solution is same as unwinding application as above.

Refer: